Dust-free & Automation

Why Dust-free

Surface Quality & Visual Standard

Premium snus cans must have flawless surfaces—free from dust specks, scratches, or imperfections. A controlled, dust-free environment ensures a clean finish that meets high visual and tactile quality expectations.Precision in High-Cavity Tooling

In high-efficiency production (e.g., 64-cavity molds), even microscopic dust can affect the mold surface or parting lines, leading to defects, uneven fits, or reduced tooling lifespan.Packaging Compatibility

Dust can interfere with downstream processes such as labeling, sealing, or stacking, especially in automated packaging lines. A clean production area ensures seamless integration and fewer production stoppages.Match Up the Best Tier in Industry

Our customers are all top tier brands. They require best quality, so we deliver the best quality.

How to Dust-free

Our largest injection machine operates at an impressive 800 tons of clamping force—pushing the boundaries of high-volume, multi-cavity production. While some claim machines of this size can’t support a dust-free environment, we’ve proven otherwise. Drawing from deep experience in the automotive industry, we made a deliberate choice to prioritize both scale and cleanliness. Thanks to the leadership of our Chief Production Officer, we've overcome the challenges and successfully maintained a 100,000-grade dust-free production environment—ensuring both efficiency and uncompromised quality.

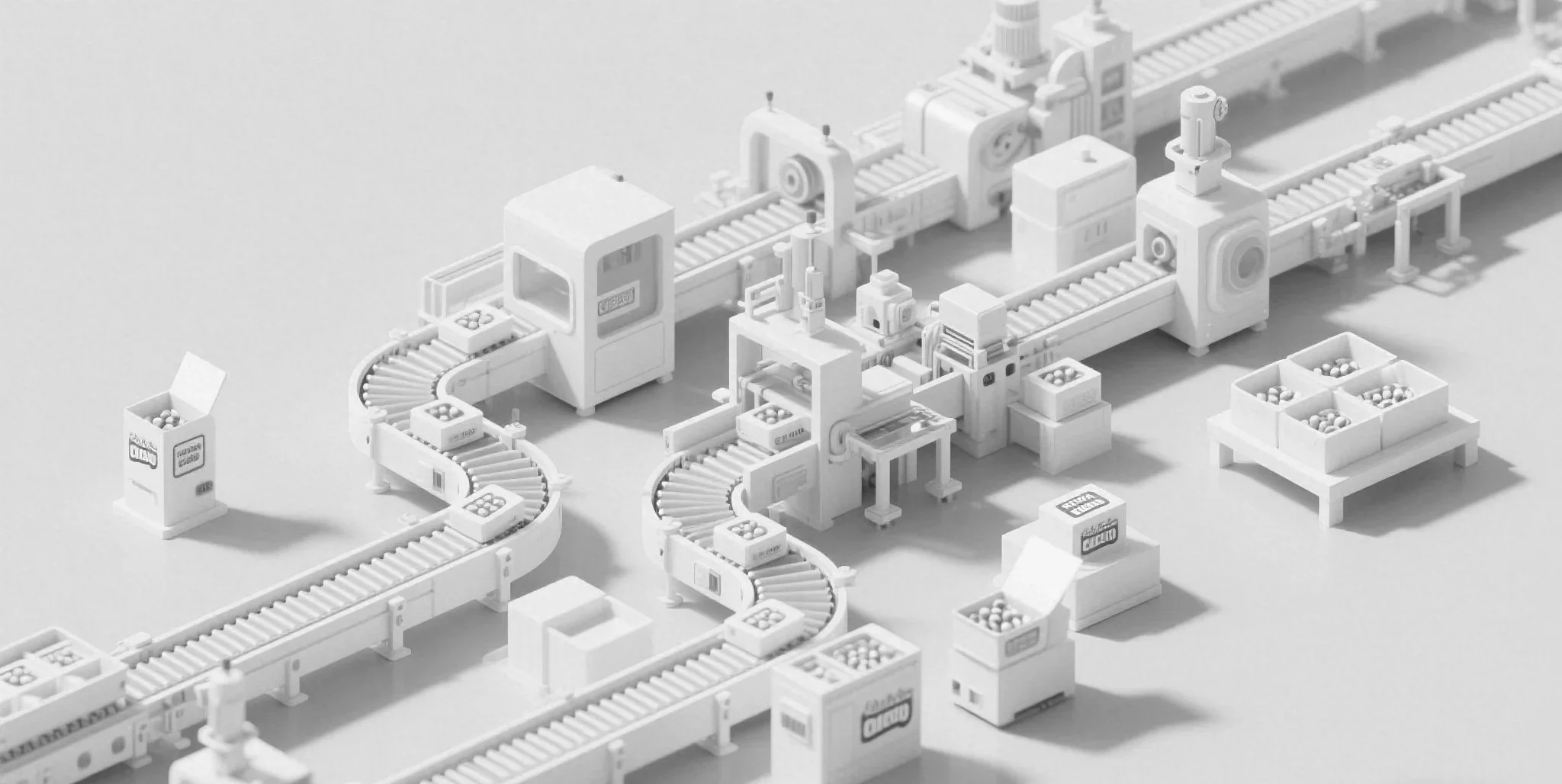

How to Automation

Backed by deep expertise in the automotive industry, we design and manufacture molds with ultra-precise tolerances—measured in dozens of nanometers. All molds undergo rigorous in-house testing using advanced tools such as white-light interferometers to ensure flawless form and finish. With certified access to leading industrial software including CATIA, Moldex3D, CAM, and more, we guarantee accurate mold flow simulation and performance from design to production.